CONTRACT MANUFACTURING

Building off of that strong foundation, and desire to control and ensure the quality of products offered, Geospace has expanded its expertise into all facets of manufacturing. With capabilities starting in microelectronics for printhead development and extending into injection molding, waterproofing, machining, and electronics/system assembly, Geospace has positioned itself as a complete turnkey option for the Contract Manufacturing Industry.

Electric Manufacturing Services

Microelectronics

Full Clean Room Capabilities Class 10K and 100K.

Die-attach, wire bonding, and encapsulation.

Cable / Wire Harness

Crimp and Poke to Complex Harnesses.

100% point to point tested.

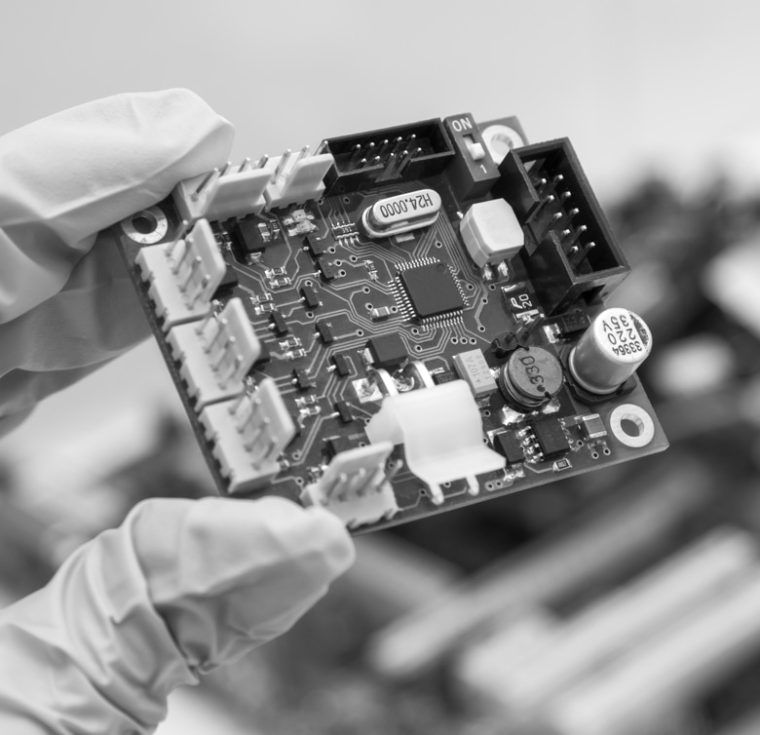

PCB Assembly

Prototyping to high volume manufacturing.

Top tier capabilities and uncompromising standards.

System / Box Build

Panel assembly, wiring, and component mounting.

System integration, cabling, and board assembly.

Precision Machining

Capabilities

40+ Machines

4 Axis mills

Turn/Mill Combos

Saws

Various Materials

CMM Measured Accuracy

Process

From up-front programming and simulation to final process measurements, we ensure quality at every step.

Capacity

With 40+ machines and the ability to add additional shifts, we can build the volume you need, big or small.

Materials

From polymers to titanium we have you covered. Other materials include: aluminum, steels, stainless, brass, composites, just to name a few.

Quality

With a focus on quality, we measure the first piece off of each machine with a CMM to ensure accuracy.

Injection Molding

We provide excellent quality, using only the best materials when we perform the manufacturing process of injection molding. This can be performed with several materials including polyethylene, polypropylene, nylons, and custom compounded plastics including glass, metal, and mineral-filled. In an effort to ensure a stable and repeatable process, we utilize automation whenever possible. This is all done with cost-efficiency in mind.

We work closely with our clients in all aspects of product design, tooling options, and material selections. This results in your injection mold project culminating to a result that you will find satisfactory. We know that one of the basic reasons for utilizing injection molding is to make cost-effective products that will drive your sales.

In addition, we strive to operate in a safe environment. Injection molding requires the use of a ram or screw-type plunger to force molten plastic material into a mold cavity resulting in the shape conforming to the mold. We want our clients to rest assured knowing that their products are being created by a team dedicated to not only using the correct processes but doing so safely.

By utilizing the best materials and keeping the tooling design and fabrication process in-house, we can control the quality and make sure it exceeds your expectations. Our flexible manufacturing operations can meet a wide range of OEM requirements efficiently and cost-effectively. As a global manufacturer, you’ll have access to a world-class team to get the quality and service you require.

Capabilities

35+ Machines with multi-shift availability

Materials: Polyethylene, Polypropylene, Nylons

Custom compounded plastics including glass, metal, and mineral filled

In House Tooling Design & Fabrication

Shot sizes up to 90oz

Design and Engineering

Geospace offers in-house tooling design and engineering support to ensure quality.

Machines

Wide assortment of machines including Cincinnati, Arburg, Wabash, AutoJector, MiniJector, and Van Dorn.

Materials

Through our partnerships with the world’s leading resin manufacturers and resin compounders we can offer solutions to complex applications.

Quality

By controlling the supply chain and having in-house tooling design and fabrication we ensure a stable, repeatable process.